For

this reason, building a whole marketing event aimed

at cynical cycling journalists is potentially a risky

proposition, but for those teams in Paris Roubaix riding

on Continental tyres - T-Mobile, Credit Agricole, Phonak

and Saunier Duval - no rider could point to an ill-timed

puncture.

According

to a report in the British Cycling Weekly, these sponsored

teams 'only' suffered two flats each in the 2005 race,

compared to the usual average of eight flats per team

in Paris-Roubaix.

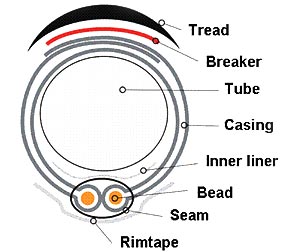

Competition-ready

Tubular tyre construction

Rolling resistance measurements for two of Continental's

high-end tyres show the Competition tubular has lower

rolling resistance than the Grand Prix 300 clincher

Tyre rolling resistance decreases as tyres become fatter,

according to Continental's measurements.

Figures from an SRM power meter show that at 50km/h

a narrow tyre requires less power than a fatter one.

Rolling resistance may be lower for the fat tyre, but

the narrow rubber's superior aerodynamics more than

makes up for it

Continental used Paris-Roubaix to introduce a new 'Competition'

model tubular: a 25mm tyre with a double layer of Vectran,

a hi-tech material that is said to offer significantly

better puncture resistance than Kevlar and other materials.

The

thin Vectran layer resides between the tyre casing and

the outer tread. The German company recognised Vectran's

strengths, but producing it so it could be used in lightweight

bicycle tyres required over two years R&D, resulting

in a secret and patented process.

The

first tyres to use this layer were used by the professionals

in the 2005 Paris-Roubaix, and the day before by a group

of journalists who all survived their cobbles experience

(see separate story).

Like

many bicycle components (or anything performance-oriented,

for that matter) the production of a tyre is a compromise

of weight over strength. Yes, tyre companies could make

a tyre that would be virtually impervious to punctures,

but it would be heavy and slow.

But

what do we mean by "slow"? How can a tyre

be "slow" - isn't it the rider? Well yes and

yes; a tyre casing that would be puncture-proof would

either be solid or so thick as to have the responsiveness

of a gumboot. A tyre still changes its shape when it

rolls down the road - regardless of the inflation -

and the energy that is required to make the tyre change

its shape is determined by its thickness. Therefore,

a thick tyre casing requires more energy than a light

casing. More energy absorbed = slower tyre.

The

challenge, therefore, is to make a tyre capable of handling

high pressure, but still be light and puncture resistant.

There are other requirements like longevity and grip,

but a racing bicycle tyre's intrinsic shape and weight

mean those qualities are almost always sacrificed in

the name of performance. We're not talking Moto GP here.

Tyres don't go off or get shredded by 180hp engines.

(Of course if you can have grip without compromising

weight and speed, then that's a bonus, and tyre development

in the last 20 years has seen substantial improvements

in rubber compounds.)

After

wind resistance, a tyre's rolling resistance is the

cyclist's next best enemy, and Continental presented

some research results that explode some myths about

tyres and rolling resistance.

Conti's

figures further demonstrate how tyre design and construction

- even at the high-end - is still a compromise of conflicting

objectives. Continental's numbers support the widespread

belief that tubular tyres are faster than clinchers,

but most surprising was research that showed how wider

tyres have less rolling resistance. For example, a 25mm

tubular offers less rolling resistance than 22mm and

19mm tyres (see graph).

But

when a bicycle and rider build up velocity, resistance

is not as important as aerodynamics, and wind resistance

becomes the all-important factor. For this reason, Continental

found that - conversely - a thinner tyre requires less

energy than a fatter tyre to travel at 50kmh, principally

due to aerodynamics (see graph).

For

this reason, Continental believes the fastest combination

of tyres is to have a 19mm front and 22m (reflected

in its Grand Prix Attack/Force combination that use

a 22mm front/23mm rear combination - see review). But

this combination was proven on the velodrome in Buttgen,

Germany. In the real world, there are factors such as

comfort, grip and not the least, puncture resistance.

What

is Vectran?

Which brings us to improving a tyre's puncture resistance

without impacting its performance. Continental clearly

believes it has the edge with the use of Vectran, and

while it is only available in the 25mm "Competition"

tubular, executives hinted at its likely introduction

into other tyres in the range.

Vectran

is - for the chemists out there - a "wholly aromatic,

liquid crystal polymer, derived from polyester"

that's five times stronger than steel. As a puncture-prevention

layer in a tyre, Vectran is said to have the edge over

materials like Kevlar because of its near-zero moisture

absorption and fatigue performance. It is also said

to have better resistance to folding and buckling -

essential if it is going to be used in high-pressure

bicycle tyres.

Conti

believes the material is also superior as a 'breaker'

material because it is more cut resistant (see table)

but still light and thin so it can be used in bicycle

tyres without adversely affecting the tyre's weight,

rolling resistance and overall performance. In short,

it is something of a breakthrough that is likely to

be featured in more products, but only for the road.

Special track and time trial models are unlikely to

feature the new material.

Time

will tell if it is more than a marketing gimmick, but

given Continental's background in bicycle tyres, it

is something the company believes will give it the edge

for years to come.

More

on 'fat tyres have lower rolling resistance'

Everyone knows skinny tyres are faster, so the notion

that fat tyres have lower rolling resistance seems counterintuitive

to many cyclists. As we've seen above, at racing speeds,

narrow tyres need less energy to maintain a speed, so

how does this fit with measurements showing higher rolling

resistance?

The

first thing to remember is that at 50km/h rolling resistance

is only a small portion of the forces acting against

a cyclist. Rolling resistance increases roughly proportionally

with speed, while air resistance increases as the cube

of speed. Double your speed and your tyres' rolling

resistance doubles - but the air resistance goes up

eight times! Air resistance dominates at racing speeds

and narrow tyres are faster.

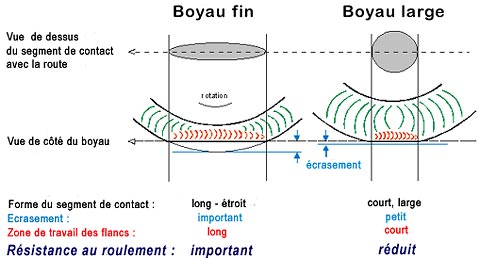

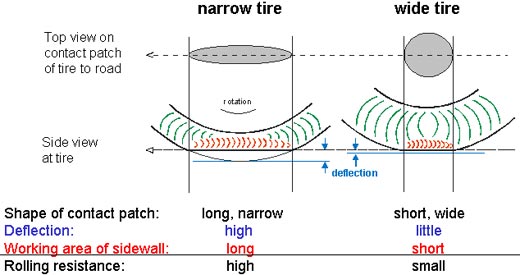

A

fat tyre gets its lower rolling resistance from the

shorter perimeter of its contact patch.

To

understand why the rolling resistance component is lower

for fat tyres, we need to understand where rolling resistance

comes from. As your tyre tread and sidewall bend on

contact with the road, they absorb energy. When they

straighten out, they spring back and return most of

that energy - but not all of it. Some of it simply gets

turned into heat, and that lost energy is the rolling

resistance.

For

a given tyre pressure and rider weight, all tyres have

about the same area in contact with the ground. If you

and your bike weigh 200lb and you have 100 pounds per

square inch of pressure in your tyres, you're in contact

with the road over two square inches of rubber (apologies

to people who think in metric, but Imperial units are

so convenient for this stuff!)